Introducing our modern White Spirit Plant & Modular Crude Refinery, will be built by the skilled engineers at Maleta sometime in end of 2025. This advanced facility will aim to create top-quality white spirits and mineral spirits for different industries like paint, coatings, and aviation. And for the importance of providing high-quality urea-based fertilizers to support healthy crop growth and maximize yields.

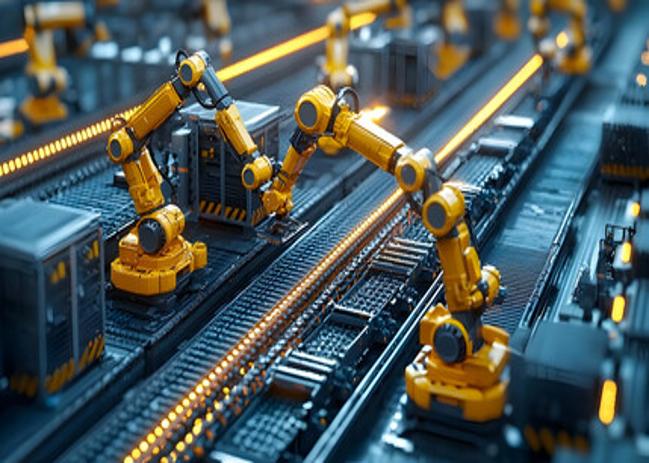

Our refinery plants will be using smart technologies for efficient separation of hydrocarbon solvents. We will focus on important steps such as tanks storage, cooling systems, and advanced automation for smooth operations.

We are committed to providing the best products for our customers. Our clients trust us to deliver high-quality results always. Our refined white spirits will prove this – perfect for use in paint thinners, driers, metal cleaning, furniture polishing, and more.

Discover the benefits of our new White Spirit Plant & Modular Crude Refinery – where smart technology meets excellent quality for outstanding performance in today’s competitive market.

A modular oil refinery is a smaller-scale, more flexible version of a traditional oil refinery. These refineries are designed to be easily constructed and commissioned in modular components, which are prefabricated and then assembled on-site. This approach allows for a quicker and less expensive setup compared to traditional refineries.

The key characteristics of a modular refinery include:

1. **Lower Capital Investment**: Modular refineries require significantly less capital investment due to their smaller size and the efficiency of the modular construction process.

2. **Crude Distillation Unit (CDU)**: The initial process in a modular refinery is the Crude Distillation Unit, which performs simple distillation of crude oil. This process separates the crude oil into basic fractions such as low octane naphtha, diesel, kerosene, and residual fuel oil.

3. **Flexibility and Scalability**: These refineries can be designed to scale up by adding additional modules as needed, allowing for incremental investment and expansion.

4. **Shorter Construction Time**: Because the components are prefabricated, the construction time is significantly reduced compared to traditional refineries.

5. **Portability**: Modular refineries can be relocated relatively easily, making them suitable for remote locations or regions with developing infrastructure.

Overall, modular refineries provide a cost-effective and time-efficient solution for processing crude oil, especially in regions where traditional, large-scale refineries may not be feasible.